- Home

- Science

-

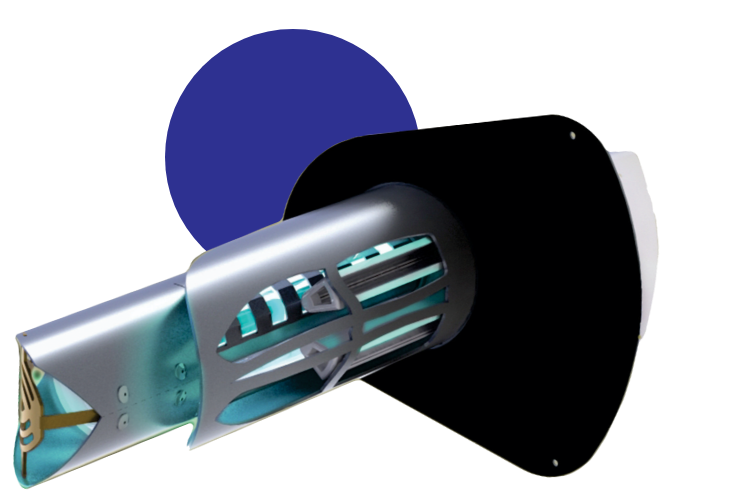

- Air Purification

-

-

Air Solutions

-

Air Resources

-

-

- Water Treatment

-

-

Water Solutions

-

AFL Solutions

-

Water Resources

AFL Resources

-

-

- Food Sanitation

-

-

Food Solutions

-

Food Resources

-

-

- Resources

-

-

-

Year In Review

Case Studies

-

FAQ

-

Popular Resources

-

-

- This is RGF

-

-

RGF Facilities

-

Careers

-

Community Partnership

-

-

-

- Contact

-