Oil Water Separators-101

Oil Water Separators

Oil Water Separators

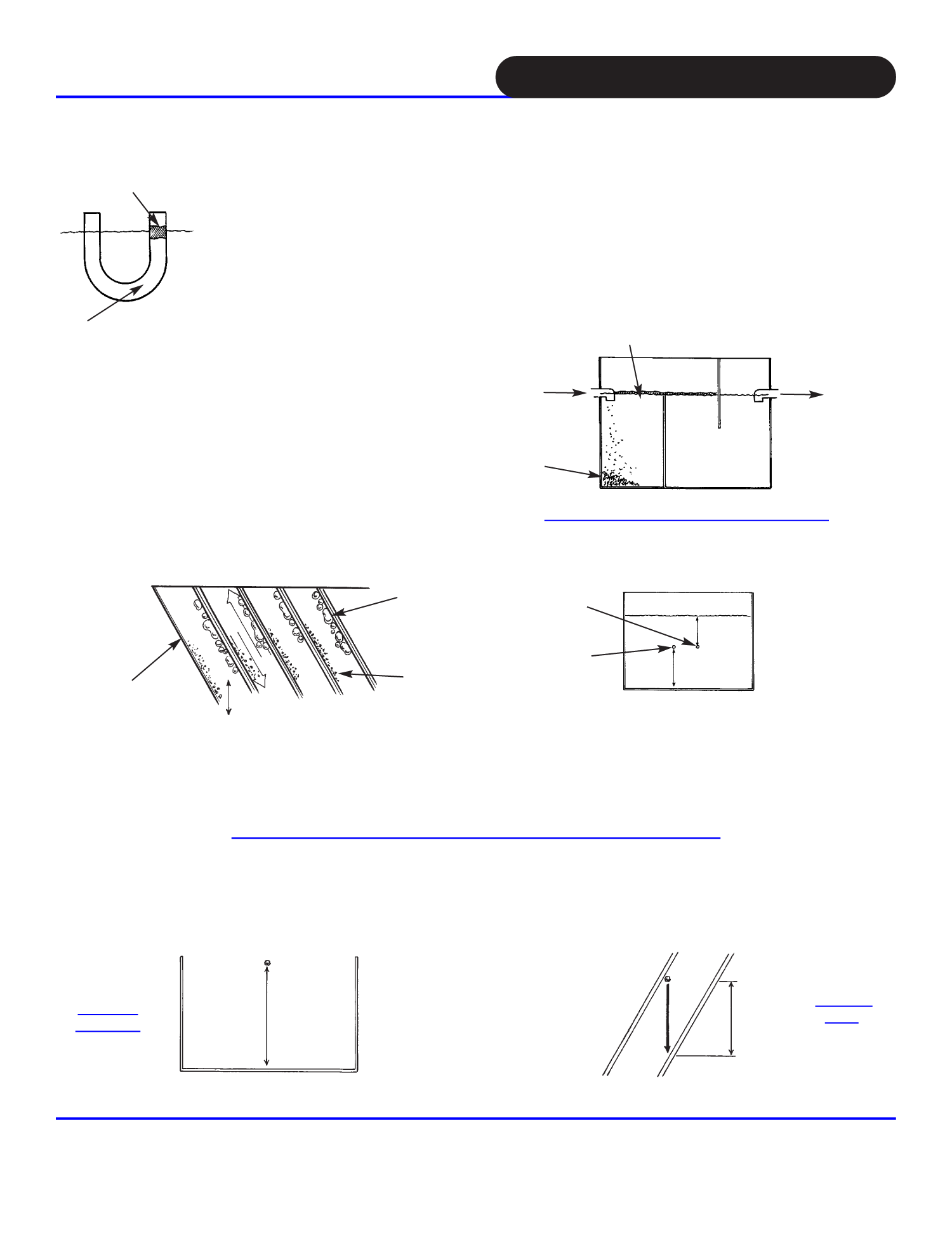

This section will cover coalescing oil/water separation. The concept of a basic gravity oil/water separator is simply a

tank vessel that stalls the flow rate to permit gravity to separate oil from water. Oil, having a lower specific gravity than

water, will naturally float on water if given time to separate.

Oil

The rise rate of oil to the surface is determined by Stoke’s Law. There are three main factors affect-

ing the rise rate: oil droplet size, oil specific gravity and temperature. Other factors include oil/dirt

particles and flow rate or turbulence. According to Stoke’s Law, a 100 micron size oil droplet will

rise three inches in five minutes. When factoring in a flow rate, you can see how a simple oil/water

separator will have to be quite large to give the oil enough time to rise to the surface. A 20 micron

size oil droplet will rise three inches in 60 minutes. Large oil droplets are more buoyant and, there-

fore, rise faster.

Water

Oil Layer

In order to reduce the physical size of the oil/water sepa-

rator, coalescors have been used successfully for many

years. The concept of a coalescor is to use oleophillic (oil

Oily Water

Clean Water

loving) media such as polypropylene or teflon. As oil and

water flow through the media, oil droplets impinge on the

media and coalesces on the surface. Coalescing, or bind-

ing together, makes them larger and more buoyant. As

Water

Settled Solids

you can see from the above example, a 100 micron oil

particle will rise three inches twelve times faster than a 20

Typical Three-Part Oil/Water Separator

micron particle.

Now to further enhance this process, we can use these coalescing media as incline plates thereby drastically reducing the

rise or fall of a particle.

Oil Globule

Oil Globule

Solids Particle

Solids Particle

Coalescing Incline Plates

By using coalescing incline plates, the rise of an oil droplet can be reduced to 1/4″ until it hits the upper surface of the

plates and glides up as it coalesces with other particles. Also, solids or dirt will settle and glide downward on the plate

surface. As it attaches to other dirt particles, the coalesced oil particles will gain buoyancy and rise rate, and the dirt

particles will gain speed as they grow heavy and settle at a faster rate.

Example:

Solids Settling – Standard Separator vs. Inclined Plates

It takes fine sand 0.1 mm diameter 38 seconds to settle 12 inches in an open tank or 114 seconds in a typical 3 ft. deep

separator. By adding 1/4 inch incline 60° plates, you reduce the settling time by a factor of 72. Therefore, the addition

of 1/4 inch incline plates will reduce the settling time of a 0.1 mm diameter fine sand from 114 seconds in a standard

separator to 1.58 seconds in a 1/4 inch incline plate separator. The same calculation can be made for oil droplet sizes

and rise time utilizing incline plates.

Inclined

Standard

36”

Plate

1/2”

Separator

Oil Water Separators

Oil Water Separators

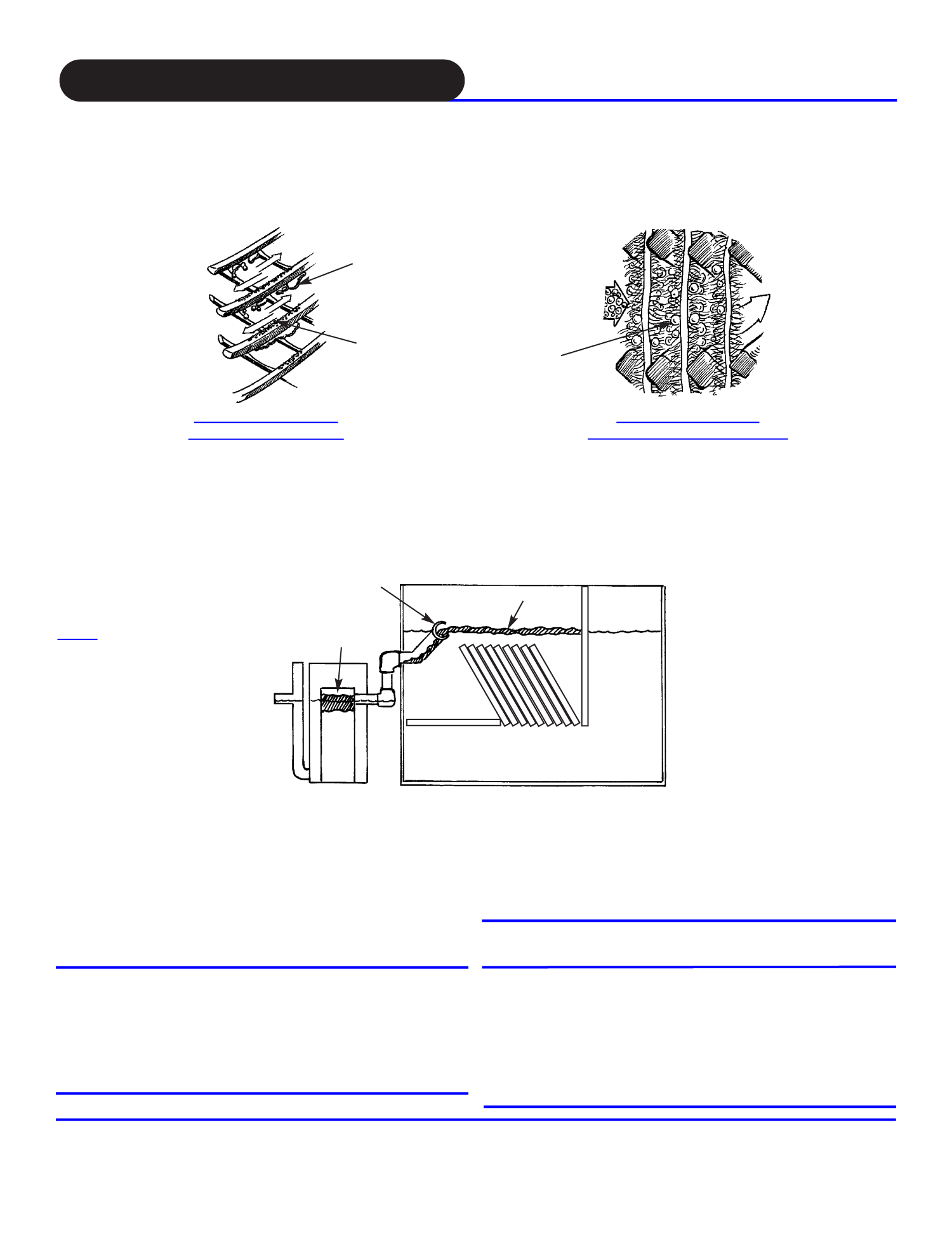

In addition to incline plate coalescing separation, RGF utilizes a Micro-Matrix Coalescor system of finely spaced poly

mesh with an incline grid matrix. For final polishing, a HCA-3 absorbent filter is recommended. This filter consists of

millions of very fine polypropylene hair-like fibers that crisscross into the water stream to attract and hold oil droplets less

than 9 microns in size.

Oil Globules

Oil Free Water

Trace Oils & Water

Solids Particles

Oil Droplets < 9 microns

in size

Magnified view of the

Magnified View of the

HCA-3 Hydrocarbon Absorber

Micro-Matrix Coalescor

This RGF system of micro matrix and HCA-3 hydrocarbon absorbers are used in our Marine Bilge Filter Systems and

has achieved results of 0.87 ppm during a two day UL/U.S. Coast Guard Test consisting of blended 25% to 100% diesel

fuel and oil under simulated sea conditions.

The addition of auto oil skimmers and the RGF Oil Accumulator makes free oil removal easy.

Oil Skimmer

Oil Layer

Accumulated

Note:

Free Oils

The use of RGF’s OWS

Bio-Disks can reduce both

free and emulsified oils by

greater than 50% using

natural bacteria

Water

Emulsified oils, either chemically or mechanically emulsified, will not separate in a gravity separator. Emulsion splitting

methods will be necessary before the emulsion reaches the separator. Alternately, quick release detergents or cleaning

chemicals can be used, which will release the emulsion and permit the gravity action to occur. Alternately, a floccing or

membrane system can be used for emulsified oily water problems.

NATURAL SETTLING

Diameter of

WATER VOLUME VS. 15 PPM OF OIL CONTAMINATION

Time Required to Settle

Order of Size

particles, mm

WATER

OIL

0.3 seconds

Gravel

10

3.0 seconds

Coarse Sand

1

in

1 Gallon

1 Drop

38 seconds

Fine Sand

0.1

in

4,000 Gal. Tanker Truck

3/4 Pint

33 minutes

Silt

0.01

in

50 gpm flow over 24 hrs.

4 Quarts

55 hours

Bacteria

0.001

(72,000 Gals.)

230 days

Colloidal Particles

0.0001

6.3 years

Colloidal Particles

0.00001

Oil Water Separators

Oil Water Separators

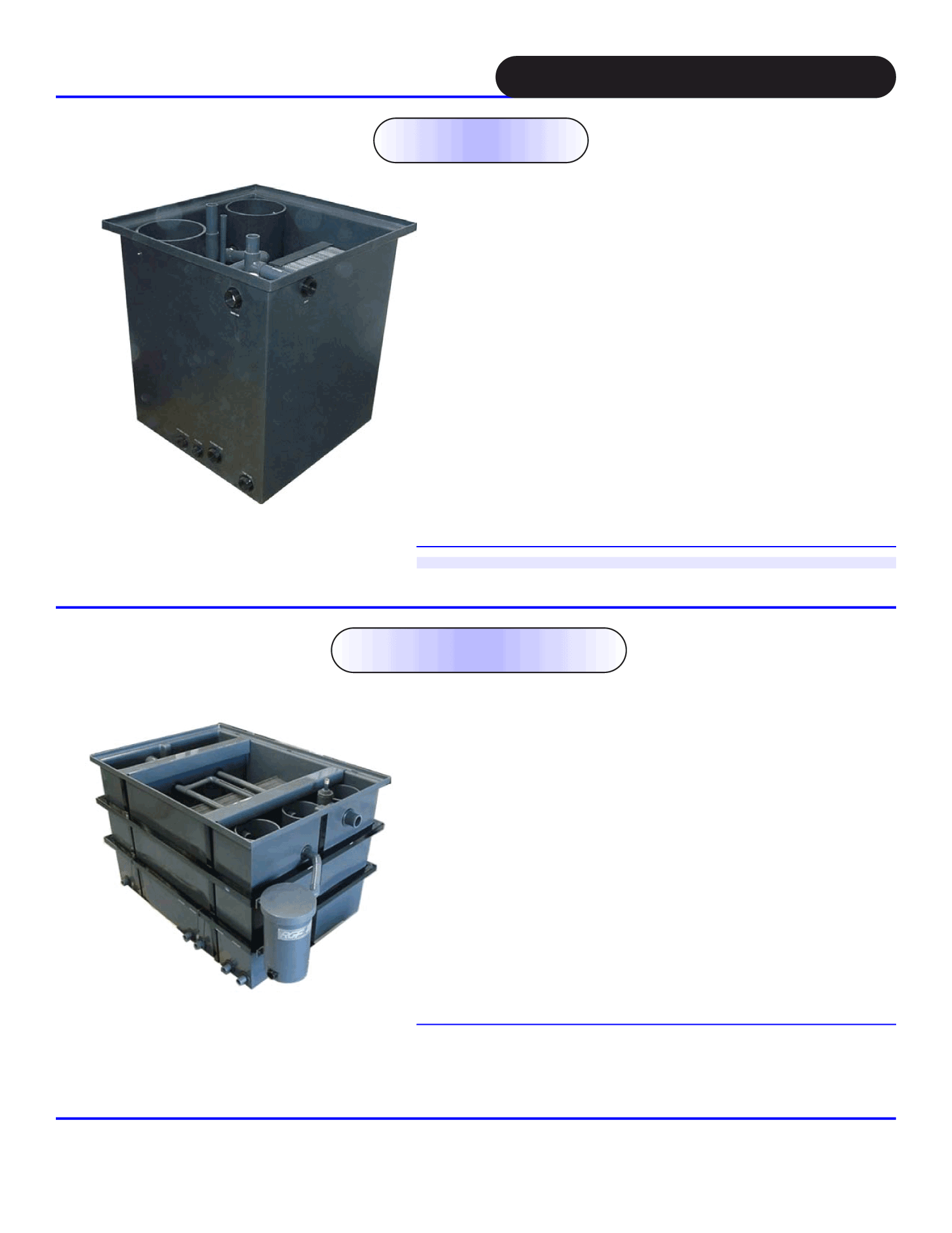

Model OWS-10

Oil Water Separator

RGF”s OWS-10 System of pre-treatment technology is

designed to avoid pollution problems by avoiding contami-

nated water discharge. It is a compact system designed to

remove free oils from water prior to discharge for sanitary

sewer or other treatment.

•

10 gpm

Flow Rate

•

35”W x 35”L x 36”H

Dimensions:

•

120 gallons

System Capacity:

•

10 gallons

Free Oil Capacity:

•

1/4” Vertical Tube Coalescor,

Separation Type:

Gravity Separation, Micro-Matrix

Coalescor

•

Polyethylene / Polypropylene / PVC

Materials:

•

RGF OWS Bio-Disks for oil reduction

Options:

Item #

Description

Ship Weight

OWS-10-Q

Model OWS-10

268 Lbs.

Fl-093

Small Permanent Coalescing Filter

Models OWS-20 & OWS-50

Oil Water Separators

RGF”s Oil Water Separators are designed to process waste-

water containing free oils. The patented systems utilize over

five technologies to remove and store the free oils before dis-

charge for reclaim or sanitary sewer.

• Flow RateOWS-20: 20 gpm

OWS-50: 50 gpm

•

OWS-20:

26”W x 50”L x 46”H

Dimensions:

OWS-50:

76”W x 56”L x 54”H

•

OWS-20:

180 gallons

System Capacity:

OWS-50:

550 gallons

• Free Oil Capacity:

OWS-20: 7 gallons

OWS-50: 7 gallons

•

1/4” Inclined Tube Coalescor,

Separation Type:

Gravity Separation, Micro-Matrix

Coalescors

•

Polyethylene / Polypropylene / PVC

Materials:

•

RGF OWS Bio-Disks for oil reduction

Options:

Shown – OWS-50

Item #

Description

Ship Weight

312 Lbs.

OWS-20A-Q

Model OWS-20

1067 Lbs.

OWS-50A-Q

Model OWS-50

FL-093

Small Permanent Coalescing Filter

SA-IP-SM-02

Small Incline Plate Pack

SA-IP-LG-02

Large Incline Plate Pack

Oil Water Separators

Oil Water Separators

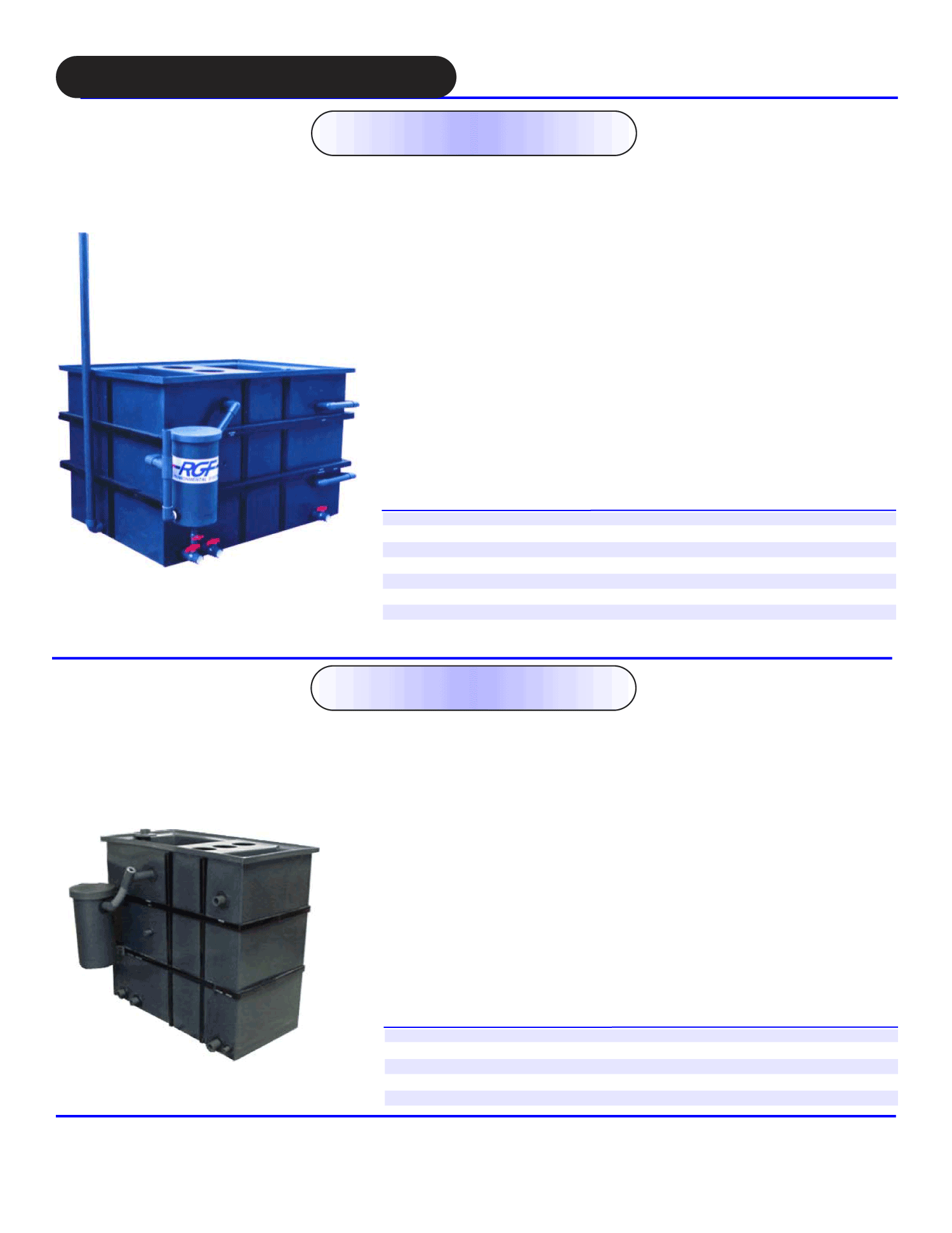

Model SD I

Sewer Discharge Oil Water Separators

RGF”s Sewer Discharge Systems are designed to collect contaminated source water, which typically contains petroleum hydrocar-

bons, heavy metals solid and cleaning fluids. The collected water is processed through the system and contaminants are removed

utilizing over 12 technologies prior to discharge to sewer.

• Flow Rate:

30 gpm

•

76”W x 56”L x 84”H

Dimensions:

•

850 gallons

System Capacity:

7 gallons

• Free Oil Capacity:

•

1/4” Inclined Tube Coalescor, Gravity Separation,

Separation Type:

Micro-Matrix Coalescors, Multi-Media Absorption

638 lbs. Multi-Media

• Final Filtration Media:

Multi-Media consists of Activated Alumina, Carbon,

Activated Carbon, Volcansorb Rock

TurboHydrozone

(XL only)

• Oxidation System:

®

•

Polyethylene / Polypropylene / PVC

Materials:

•

RGF OWS Bio-Disks for oil reduction

Options:

Coalescing Centrifugal Separator (XL only)

Ship Weight

Item #

Description

726 Lbs.

SD-I-Q

Model SD-I

756 Lbs.

SD-I-XL-Q

Model SD-I w/ TurboHydrozone

& H.E.C.S.

®

OI-002

Coalescing Separator for Model SD-II

OI-004

TurboHydrozone

for Model SD-II

®

Fl-096X

HCA-2 Filter – SD-I & SD-I-XL

Fl-101

Filter Media – SD-I & SD-I-XL

Model SD II

Sewer Discharge Oil Water Separators

• Flow Rate:

15 gpm

•

56”W x 32”L x 54”H

Dimensions:

•

250 gallons

System Capacity:

7 gallons

• Free Oil Capacity:

•

1/4” Inclined Tube Coalescor, Gravity Separation,

Separation Type:

Micro-Matrix Coalescors, Multi-Media Absorption

161 lbs. Multi-Media

• Final Filtration Media:

Multi-Media consists of Activated Alumina, Carbon,

Activated Carbon, Volcansorb Rock

•

Polyethylene / Polypropylene / PVC

Materials:

•

RGF OWS Bio-Disks for oil reduction

Options:

Ship Weight

Item #

Description

310 Lbs.

SD-II

Model SD-II

OI-002

Coalescing Separator for Model SD-II

OI-004

TurboHydrozone

for Model SD-II

®

FL-012

Filter Media – SD-II

FL-001-X

HCA-2 Filter – SD-II

Click Here for PDF