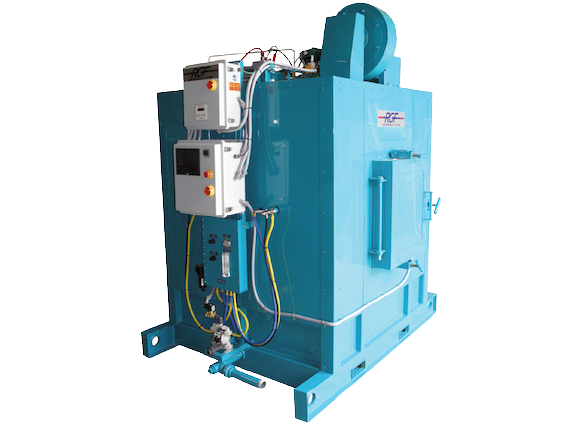

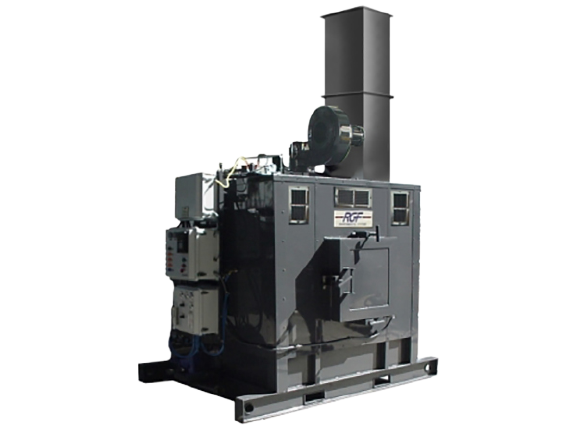

Thermo-Oxidizer: Dry Chamber Flash Evaporation System

The RGF Thermo Oxidizers are a unique method of liquid destruction. Through Flash Evaporation, the liquid waste is atomized and sprayed under pressure into a dry, ceramic refractory lined chamber. At 1250°F, all VOC’s and organics are oxidized and dissolved while suspended solids are oxidized to ash. Solid contaminants are reduced to a powdered inorganic ash for easy removal. The unit eliminates the typical evaporator problems of corrosion, foaming, residual slurry, VOC emissions and difficult to clean evaporator chambers. By utilizing an optional waste oil burner, the system can eliminate both waste oil and wastewater.

REQUEST A QUOTE